Product Description

The AVOTurboworld Y61 Patrol 4.8L was first developed in the 1990’s and over the years has been improved for total reliability.

When we first designed this kit we wanted to ensure that it had an OEM style look under the bonnet. It had to work with the standard airbox which was vital for the keeping of water and sand out of the engine and especially in the particular regions the kits may be fitted. The turbocharger had to be low mounted to enable under bonnet heat to be able to dissipate as quick as possible.

We designed a high temperature stainless cast 2 piece manifold to mount the turbocharger under it. The manifold is ceramic coated and bolted to the top of the manifold is a brushed stainless heat shield. The turbocharger is an AVO6366 which is capable of producing enough air flow to make up to over 400 kilowatts at the wheels if pushed. The turbocharger runs a T3 1.3a/r ceramic coated integrally wastegated exhaust housing with a 42mm flapper valve. This will prevent any boost overrun and keep back pressure to a minimum. Off the back of the turbocharger is a ceramic coated cast outlet that joins to the full turbo back exhaust system. We have an option for the exhaust in full 3” stainless with 1 muffler and 1 resonator, this allows for good flow along with minimal exhaust and cabin noise. The exhaust front pipe has flex to allow movement and prevent any cracking forward of it. There is an option for a cat converter to be fitted into the front pipe for emissions if required.

Oil & Water plumbing for the turbocharger needed to be the right size and with a combination of high temperature braided and rubber hoses. In routing the lines we made sure it was away from the manifold piping and crossover by using p-clamps to hold them in place.

Intake and intercooler hosing and piping is to finalize the kit before the hardest task of completing a ECU tune. We elected to use one piece wire reinforced silicon hosing for the intercooler hot and cold side and a combination of mandrel powdercoated black steel piping. For the intake side, there is a combination of powdercoated aluminium piping and silicon joiners from the airbox to the turbocharger.

The OEM style plastic BOV allows the air to bypass from the aluminium intake pipe to the steel intercooler pipe. The reason for the OEM style BOV is to stop any dirt or sand getting into the turbo system and of course to keep the turbocharger from stopping and starting.

For fueling requirements, an inline adjustable fuel regulator replaces the factory non-adjustable version and attaches to the end of the fuel rail. Bolts in the original spot. Testing also revealed that an upgrade fuel pump was required. We also included an upgrade 245lp/hr fuel pump that bolts inside the factory fuel tank.

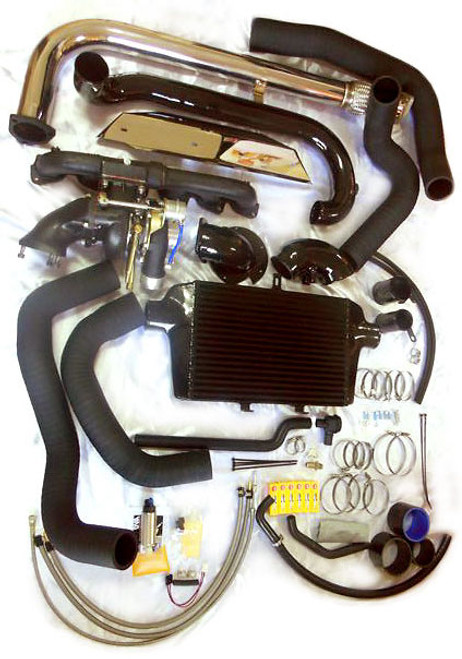

The kit includes the following:

1. Stainless 2 Piece Cast Turbo Manifold with Ceramic Coating

2. Stainless Cast Turbo Outlet with Ceramic Coating

3. Inconel Studs, Stainless Washers & Stainless Nuts

4. AVO6366 Turbocharger with Internally Wastegated 1.3A/R Exhaust Housing with 42mm Flapper Valve & 5psi Actuator

5. 3.5” Thick Front Mount Bar & Plate Intercooler Core with cast Aluminium End Tanks.

6. Combination of mandrel bent steel/aluminium powdercoated black intercooler/intake piping and high pressure wire reinforced silicone intercooler hosing

7. OEM Plumb Back Style BOV

8. Braided Oil & High Temperature Rubber Water Plumbing – all pressure tested and of the highest quality

9. High Volume Bolt-In Fuel Pump

10. Adjustable Bolt-In Fuel Regulator

Australian Dollar

Australian Dollar

NZD

NZD

EUR

EUR

US Dollar

US Dollar